Wiring

I’ve been struggling to work out the wiring for the TB6560 stepper motor driver and the Mach3 parallel port breakout board.

Now that I have figured it out, I figured that I would share a schematic for all posterity.

How to wire up the extras

How to wire up the TB6560 stepper driver

How to test the parallel port

Limit Switches

Linux CNC

Linux CNC is great.

I got a result of 26125 ns on the base thread from the Linux latency test.

This steps per mm calculator is useful for configuring LinuxCnc. An alternative is gSender

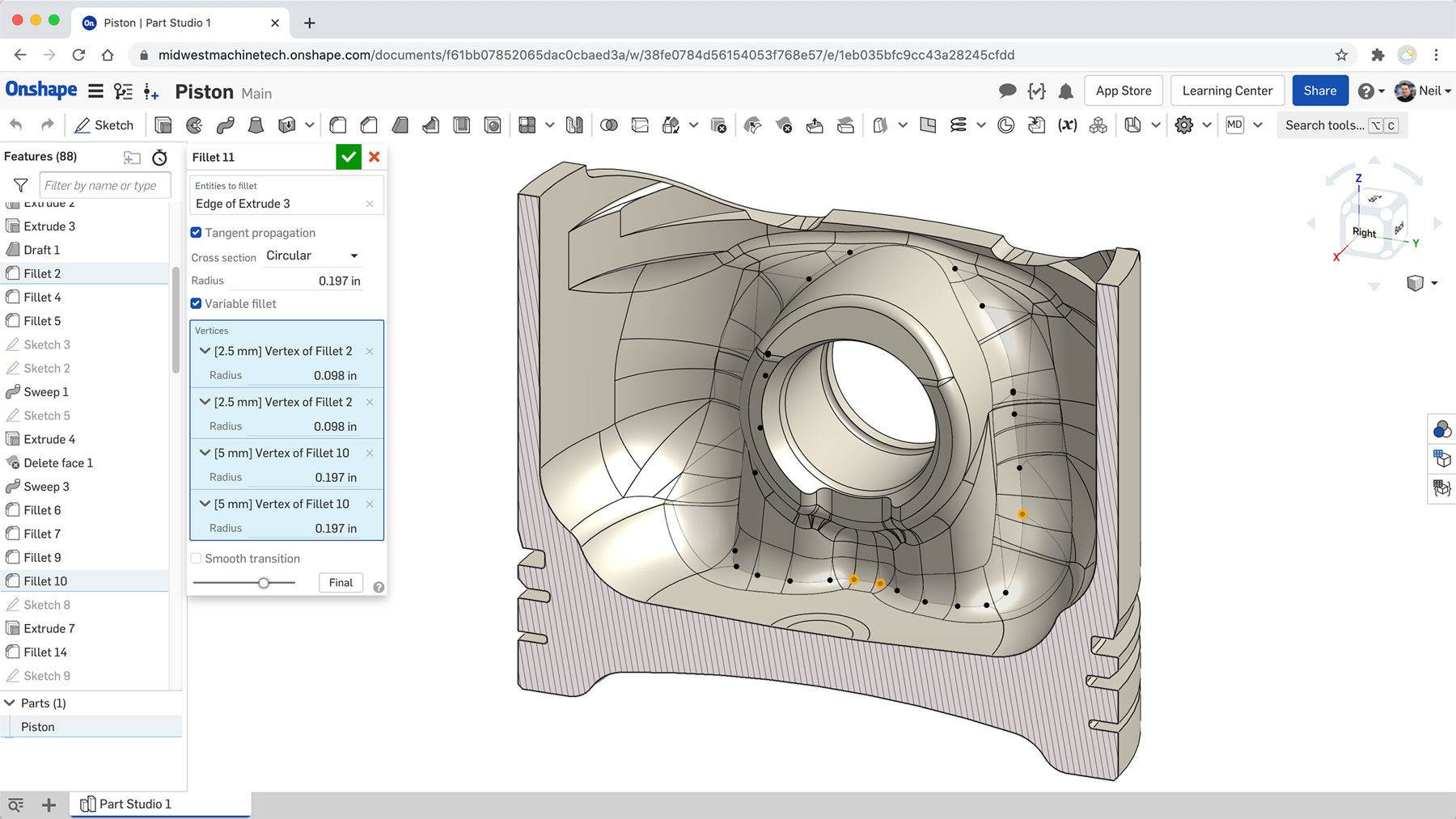

CAD

I use Solidworks, an alternative might be freecad, since it has CAM built in. Fusion360 also has built in CAM, apparently.

Onshape looks like a good option, it has a free version for openSource hobbyists and integrates with kiri.

CAM

CAM programs take your CAD model and, together with information such as bit size, material being cut, etc, use it to create g-code. CAM is probably the biggest issue in this whole workflow. There is a distinct lack of options. There is a wiki which has some potential options. This toolchain wizard is a helpful tool for some of the options.

From my reading, the options are, in order of preference below:

2D

- CAMLAB and Kiri, a starter tutorial - Free

Kiri is actually very cool and supports, 3d printing, laser cutting and cnc routing!

- ESTLCAM - $59, but you can download an older version

- bCNC - free

- DXF2Gcode - Free!

- MakerCAM, Github, basic tutorial - Free

- Easel - Free, very basic but easy to use.

- OpenBuildsCAM - Free, but doesnt work very well with DXF

- Carbide Create - Free, but doesnt work very well with DXF

- Web based and this - Free

- PathCam - free, didnt work with solidworks STL

Recommendation

EstlCam or CamLab/Kiri.

3D

- MeshCam - $250

- VCarve - $400

- HSMWorks CAM addon for Solidworks - $495 per year

- Freemill plugin for Solidworks - upwards of $600, depending on version

- CamBam - $150, but you can download an older version

- PyCam - linux only at the moment - Free

Recommendation

Cambam or meshcam, based on price.

Alternatives

Buy

Expensive, but at least they do the job, some include software for toolchain from CAD to gCode.

- Bantam desktop machine - $3 600

- evo One - $4 300

- ShopBot desktop machine - $7 600

- Carbide3d Nomad desktop cnc - $2 800

- ShapeokoPro3 -$ 2600

- Cheap milling machine and CNC conversion kit, like this - approx $1 600

- Openbuilds-c-beam-machine - $700

- Openbuilds mini mill - $550

- Bulkman mini mill rip off - $200

- Bulkman c-beam rip off - $233

Build

Noise, dust, frustration! Not to be understestimated! Making something stiff, square and repeatable is not a small task. The smaller, the better here; both for stiffness and to build an enclosure.

Fixed vs moving gantry

Decide whether a fixed or moving gantry is better, considering rigidity and squareness, as well as size constraints.

Fixed gantry example

Another example

Construction methods

To be honest, unless you already have access to precision tools, it may be better to build your own lasercutter or plasma cutter instead. In order of preference:

- Cast from epoxy granite - at least this allows for taking your time making a mould and making sure its all square. Once its set, no take backsies though! Here and here. Will also need quality components. Another good example

- Weld a steel frame. You will need to spend much time grinding and lapping to make it flat and much time making it square. Will probably require granite parallels

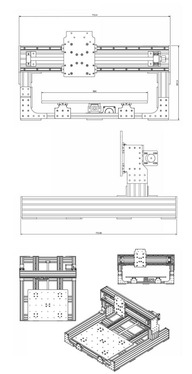

- Aluminium extrusion frame - these are the most accessible and there are plenty designs out there. The few which I have tried have been almost commically flexible when milling material, so design needs to be bulletProof. Perhaps, these designs are worth considering: here and here or here or here

Both options are available from his store and here

CnC from openbuilds with rails and here

One which uses some 3d printed add ons

From here

This one below has been filled with epoxy granite.

More info in the build log.

With more details here

- Full Granite

Some more info here

Flatness

It is important to get everything as flat as possible. Epoxy levelling seems like a potential approach in a diy setting, although it also has problems, with uneven temperatures and a meniscus at each edge being some of the problems, you also cant move it, since twisting could distort the epoxy.

Alternatively, use granite.

Lapping is probably a better option, but time consuming.

Explanation of how to make your own lapping plate below:

Explanation of the whitworth method

Commercial lapping operation in SA.

Alternatively, buy or build a surface grinder.

Squareness

granite parallels or granite table top offcuts in a pinch.

Rigidity

Filling aluminium profiles with steel bar and epoxy granite also seems like a good solution.

Leadscrew vs ballscrew

Dust Shoe

Milling is extremely messy. A dust shoe is a necessity and a split one seems like a good idea.

Comments